Water Bottling Machine

Product Details:

Water Bottling Machine Price And Quantity

- 1 Set

- 750000.00 INR/Unit

Water Bottling Machine Trade Information

- 30 Set Per Month

- 3 Week

- Asia South America Western Europe Middle East Africa Eastern Europe

Product Description

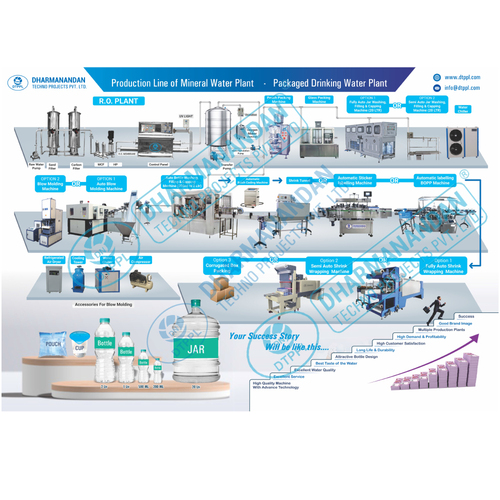

DTPPL'S WATER BOTTLING PLANT:

The Water Bottling Machines we offer are featured with raw water tank that can store raw water and come with proper flow and pressure. These deliver the raw water to the system and are controlled by PLC. These systems are also used in RO systems to eliminate dissimilar types of particles, such as colloidal compounds, suspended solids (turbidity) etc. Water Bottling Machines are commonly used for removal of organic substances and heavy metal element, suspended solids and etc. The systems can be cleaned timely and come with filter, disinfectant tank, valve and other mechanisms.

Whole Line Technical Process:

1.Raw water tank

It use to storage raw water, Stable Ro system raw water flow and pressure, protect the raw water pump. The raw water tank with built-in water stainless steel ball valve and liquid level controller.

2. Raw water pump

Brand: China South Pump. It will deliver the raw water to the system, it is control by PLC. Liquid level controller can control the booster pump start and stop.

3. Quartz sand filter

It is widely used in RO system to remove different types of particles, such as suspended solids (turbidity), colloidal compounds and etc. This process will reduce the load on the back-end filters

4. Carbon filter

the active-carbon filter is commonly used for removal of organic substance and heavy metal element, suspended solids and etc. It can effectively reduce the level of COD and improve the taste of water. After the quartz sand filter and active carbon filter, the water basically required the water treatment plants water standard: SD1

5. Security filters:

Prevent the particles entering the membrane, scratched the surface of the membrane. In the normal operating condition, the filter can maintained for 3 mouth. The filter structure for fast replace.

6. High pressure pump.

High pressure pump is mainly to add pressure of the inlet water into a certain standard so that the pressure difference will be enough for the Reverse Osmosis need.

7. RO Membrane

it can removes the hydronium, organic substance, colloid, bacteria and other impurity by the method of membrane. And the water can be desalted and purified. The theory is as follows. The treated water and the untreated water are separated by the membrane; the treated water osmoses to the untreated water,There is osmotic pressure between the two. If the pressure is added to the untreated water and the pressure of the untreated water is bigger than the osmotic pressure, the water of the untreated water osmoses to the opposite position of the water. This applies the reverse osmosis to the desalted water. That is to say the untreated water is purified into the pure water through the RO membrane under adequate pressure. The left water which cannot osmosis through the membrane contains a lot of solute and suspended substance, and it will be drained out as waste water.

The water must be pre-treated before entering into the RO system, or it will bring damage to the RO membrane.

The RO system not only can be used for desalination, but also for filtering the organic substance and bacteria.

The production of water is monitored by the liquid crystal display conductivity meter.

The RO system needs be cleaned timely, including the stainless steel pump, filter, disinfectant tank, valve and other components.

Commonly, the RO system should work once every day. If it does not work in one week, it must be protected by some measures, or the service life of the membrane will be serious affected.

Other Products in 'Bottle Filling Machine' category

|

DHARMANANDAN TECHNO PROJECTS PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |